About

In the winter of 2010, Botos Design & Distribution Inc. set out to design and manufacture a more efficient model helicopter rotor blade for flybarless helicopters. Extensive research was performed involving both flybarless electronics experts as well as aerodynamics experts which uncovered airfoil efficiencies that are now implemented in the design of Rail Blades. The efficiencies of this custom airfoil are revealed in faster forward flight speed while maintaining stability, excellent cyclic response around center stick, cooler running power systems and servos. Other widely used “standard” airfoils such as NACA-0013 showed dramatic increases in amperage draw and motor loading as well as less collective and cyclic response than the custom Rail Blade airfoil.

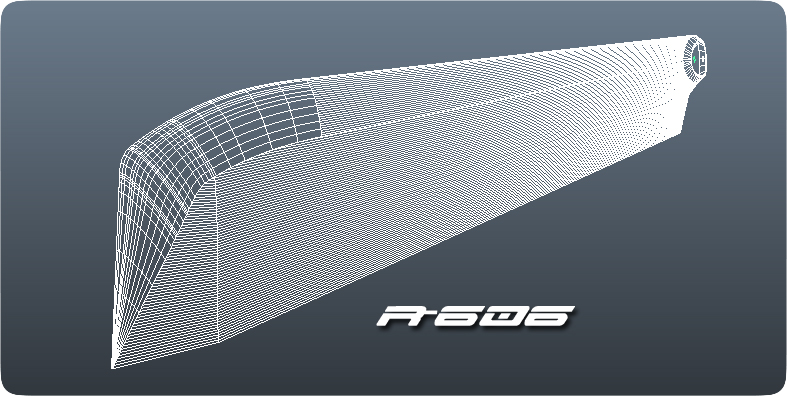

With Rail Blades, nothing about the design is arbitrary! The tip of a rotor blade is one of the most important features of the rotor blade design. Many rotor blade manufacturers simply design a tip that looks good without considering the importance of efficiency. If you have ever heard a rotor blade flutter during aggressive maneuvers it is because the rotor blades are coming out of track, this is mainly due to a poorly designed rotor blade tip. Rotor blades that make excessive noise such as whistling and fluttering are consuming priceless energy that your helicopter should be using to accelerate itself through the air. Rail Blades are the first to have been designed with an ultra efficient rotor blade tip which delivers unparalleled power and silence. Do the blades on your helicopter whistle or flutter? Bolt on a set of Rails and give your helicopter the efficiency it deserves! Accept nothing but the best…..Fly on Rails!

Rail Blades are designed and tested in the USA by Botos Design & Distribution Inc. If you wish to become a Rail Blades dealer please send us an email via our contact form.